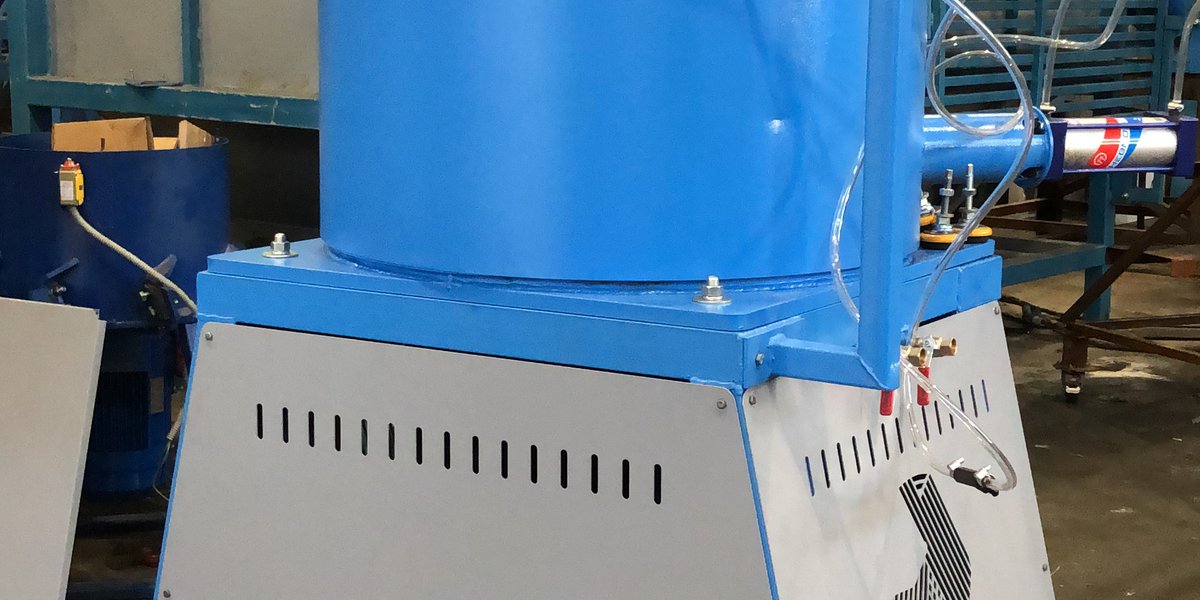

Agglomerator

-

Affordable prices

Affordable prices

-

2 years warranty

2 years warranty

-

Modern production

Modern production

-

Wood packaging

Wood packaging

-

High-level service

High-level service

Сharacteristics

| Production output, kg/h: | from 130 to 400 |

| Power, kWt: | from 55 to 90 |

| Rotor speed, rpm: | 1500 |

| Dimension, LxWxH: | from 750x1030x2080 to 1400x1030x2080 |

| Working capacity (HxL), mm: | from 1000x800 to 1000x1000 |

| Weight, kg: | from 971,1 to 1352,3 |

After the waste was thrown into the machine pot, the material is rapidly cut into pieces by the shearing action of the high-speed rotating rotary blade and the fixed blade. The shredded material or sheet flows along the inner wall of the pot body under the centrifugal force of the rotary cutter plate. At the same time, the material under the paddle is turned up and down again and moves around from the center to the direction of the pan body. Due to the friction between the material itself at high speed and the friction between the material and the wall and the blade, a large amount of frictional heat is generated, so that the material temperature rises rapidly to half In the plasticized state, they stick together into small pieces. Before the material is about to be agglomerated, the quantitative water that is prepared in advance is sprayed into the material. The cold water meets the hot material and quickly vaporizes, taking away the heat from the surface of the material. The surface is cooled rapidly to prevent agglomeration and then shredded into pellets (aggregated and irregular aggregates) by the breaking action between the rotating blade and the stationary blade. During the shredding process, suitable pigments may also be added for coloring as needed.

The pre-granulated material (from 0-10 to 0-30 mm depending on type) is conveyed continuously from a feed silo through the center of the fixed disc into the processing area by means of a feed screw. The material is rapidly heated up by the friction against and between the compactor discs.

RANGE

-

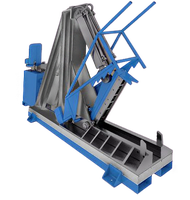

Agglomerator PZO-A-55

Production output, kg/h: 130-230

Power, kWt: 55

Rotor speed, rpm: 1500

Dimension, LxWxH: 750x1030x2080

Working capacity (HxL), mm: 1000x800

Weight, kg: 971,1

4 240 $ -

Agglomerator PZO-A-75

Production output, kg/h: 300

Power, kWt: 75

Rotor speed, rpm: 1500

Dimension, LxWxH: 950x1030x2080

Working capacity (HxL), mm: 1000x900

Weight, kg: 1243,7

5 565 $ -

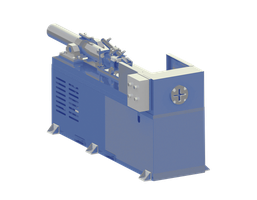

Agglomerator PZO-A-90

Production output, kg/h: 400

Power, kWt: 90

Rotor speed, rpm: 1500

Dimension, LxWxH: 1400x1030x2080

Working capacity (HxL), mm: 1000x1000

Weight, kg: 1352,3

6 760 $

Possible materials

-

Films

Films