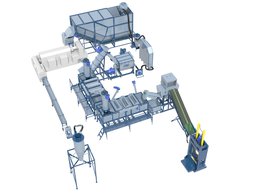

- Capacity 800.0 kg/h

- Installed capacity 264.0 kW

- Practical capacity 184.8 kW

- The line includes 22 units

Recycling line for film and filamentary materials PZO 800 MKG-S

-

Affordable prices

Affordable prices

-

2 years warranty

2 years warranty

-

Modern production

Modern production

-

Wood packaging

Wood packaging

-

High-level service

High-level service

Description

LINE'S COMPOSITION

-

Guillotine GGR 1400

7 700 $ -

Band Transporter PZO 600/4000-TL

2 415 $ -

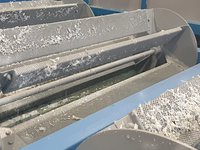

Crusher PZO-801 DLS

13 200 $ -

Intermediate Tank VB300RE

678 $ -

Sink Float Tank PZO-VF301

11 995 $ -

Centrifuge PZO 520-CV

2 515 $ -

Sink Float Tank PZO-VF301

11 995 $ -

Centrifuge PZO 520-CV

2 515 $ -

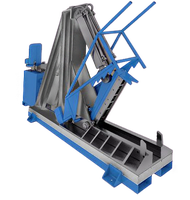

Tilting Centrifuge CN. 300-3000

7 220 $ -

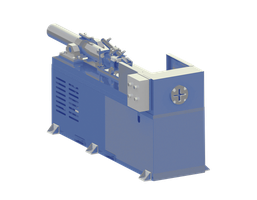

Horizontal Whirler PZO.CG.500

10 705 $ -

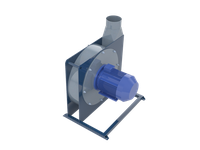

Centrifugal Fan PZO-3-MUX

628 $ -

Duct Heater

2 470 $ -

Centrifugal Fan PZO-11-MUX

1 400 $ -

Spiral Dryer

3 922 $ -

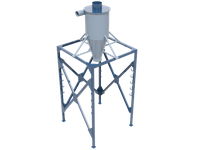

Cyclon C-450-1A-Z

955 $ -

Centrifugal Fan PZO-5,5-MUX

785 $ -

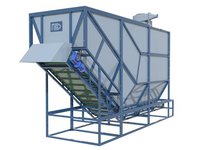

Hopper Storage

8 193 $ -

Side Feeder

6 770 $ -

Centrifugal Fan PZO-3-MUX

628 $ -

Cyclon C-450-1-D

799 $ -

Big Bag Holder DB-2500

746 $ -

Assembly Kit

4 725 $

Possible materials

-

Films

Films